Dr. J. A. Barreiro & Assocs.-Cargo Inspection Service ofrece el servicio de consultoría para el transporte marítimo de carga en contenedores refrigerados y secos, evaluando los siguientes aspectos:

-

-

- Condición de contenedores (refrigerados y secos) incluyendo:

-

Evaluación física visual de la unidad.

Preparación y limpieza.

Inspección para detectar infestación.

Revisión de la etiqueta de PTI (Inspección de pre viaje) y la etiqueta para el cargamento (carga refrigerada).

-

-

- Configuración de parámetros de carga refrigerada: Temperatura de set point, intervalo de descongelación del evaporador, intercambio de aire, humedad relativa, composición de gases y preparación de la unidad para atmósfera controlada.

- Requerimiento de los empaques.

- Estiba.

- Trincado de la carga.

- Evaluación del embalaje, paletizado, estiba y trincado en contenedores y su incidencia en el flujo de aire en la unidad (contenedores refrigerados).

- Planes estadísticos de muestras para análisis de laboratorio. Sellado, identificación, custodia y trazabilidad de las muestras para ser entregadas en un laboratorio local.

- Procedimientos para evaluar la ccondición y apariencia del producto.

- Evaluación de la madurez, presencia de enfermedades, desórdenes fisiológicos y defectos en frutas y verduras) de acuerdo a un muestreo estadístico (a pedido del cliente).

- Análisis físicos y químicos in situ utilizando pruebas rápidas (humedad, tamaño, textura,, a pedido del cliente).

- Presencia de embalajes defectuosos: unidades rotas, manchadas, golpeadas, deformadas, mal cerradas.

- Evaluación de la temperatura de la carga y estadística al momento de ser estibada o vaciada.

- Relación de hechos y tiempos durante la estiba de la unidad incluyendo precipitaciones, temperatura y humedad relativa ambiental.

- Revisión de parámetros de cantidad: tipo, número de envases, pesos y marcas de acuerdo a la lista de empaque.

- Cumplimiento con la carga máxima declarada para el contenedor (VGM)

- Colocación del precinto de seguridad.

- Revisión de registros fotográficos/audiovisuales del proceso de llenado o vaciado del contenedor.

- Cálculo de desecantes para prevenir la condensación en contenedores secos.

-

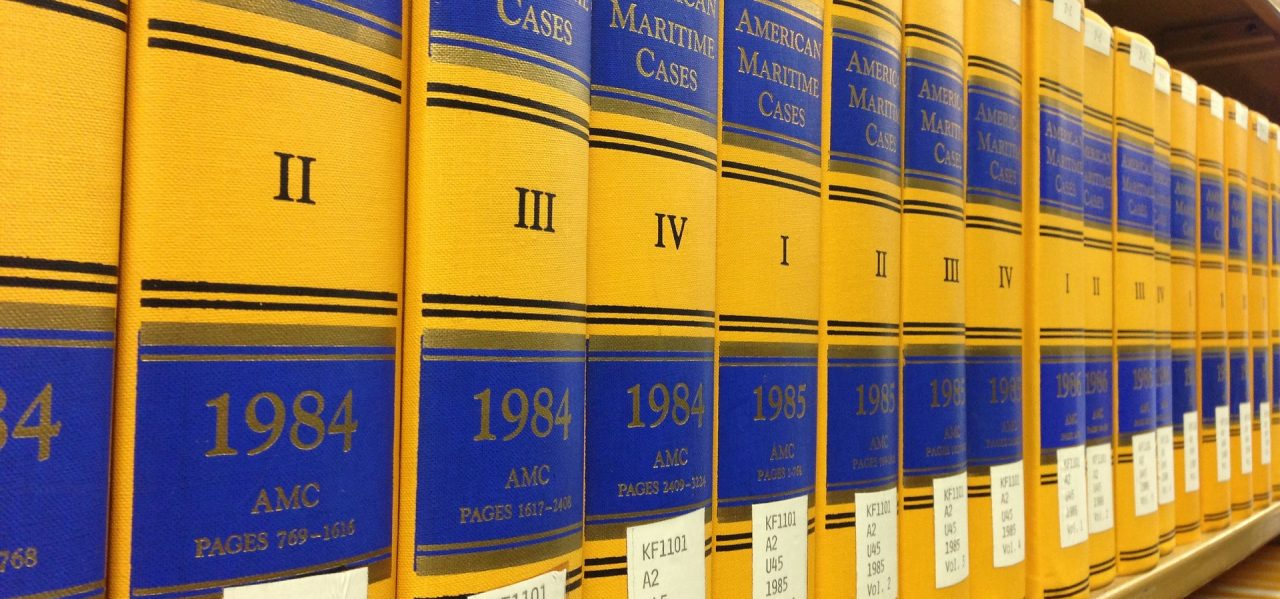

Documentos usualmente requeridos para una inspección