|

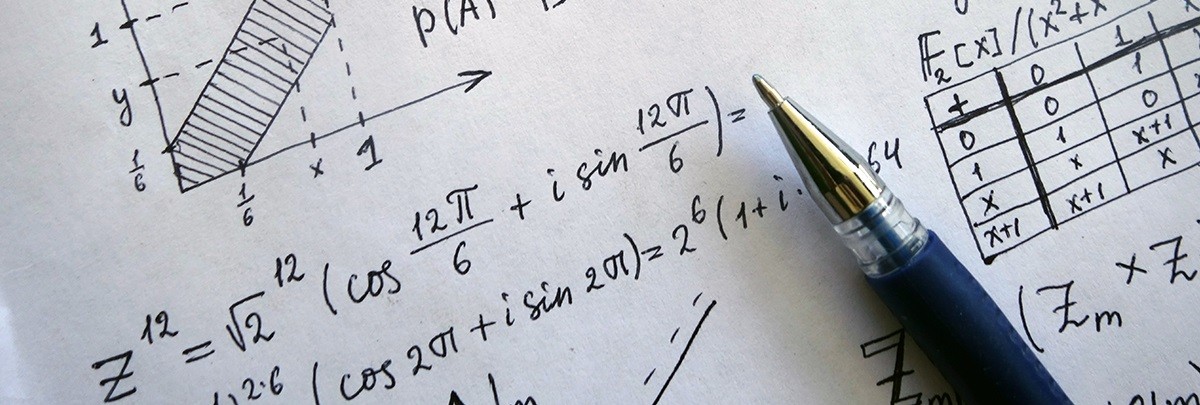

TEMPERATURA Y HUMEDAD RELATIVA AMBIENTAL EN VARIAS CIUDADES DE VENEZUELA AMBIENT TEMPERATURE AND RELATIVE HUMIDITY IN VARIOUS CITIES OF VENEZUELA En este informe se presentan los datos meteorológicos históricos para diversas ciudades de Venezuela, incluyendo temperatura y humedad relativa ambientales. Estos datos son de importancia para los cálculos de refrigeración y estimación de cargas térmicas e infiltración en almacenes y contenedores refrigerados.

Fuente: Promedios climatológicos de Venezuela, 1951-1980 (Anon., 1983) (c) Prof. Jose A. Barreiro, M.Sc., Ph.D. Dr. J.A. Barreiro & Assocs |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Información Técnica

-

AGUACATE: TRANSPORTE MARÍTIMO EN CONTENEDORES REFRIGERADOS E INSPECCIÓN DE CARGA. e-Book en Español USD 45

-

TRANSPORTE MARÍTIMO E INSPECCIÓN DE BANANAS Y PLÁTANOS EN CONTENEDORES REFRIGERADOS. e-Book en español $35. Barreiro J. A., 2021.

-

TRANSPORTE MARÍTIMO DE AJO EN CONTENEDORES REFRIGERADOS, CON ESPECIAL MENCIÓN AL AJO CHINO. e-Book en español $35. Barreiro J. A., 2021

-

TRANSPORTE MARÍTIMO DE CACAO Y CAFÉ EN CONTENEDORES Y BODEGAS DE BUQUES. e-Book en español $35. Barreiro J. A., 2021.

-

TRANSPORTE MARÍTIMO DE ACEITES, GRASAS Y PRODUCTOS LÍQUIDOS EN TANQUES: MEDICIÓN Y CÁLCULO DE VOLUMEN Y PESO. e-Book en español $35. Barreiro J. A., 2021.

-

Aguacate Hass: Modelo matemático para estudiar el efecto de la temperatura en la calidad y vida útil durante el almacenamiento y transporte en contenedores refrigerados

-

MODELO MATEMÁTICO PARA ESTUDIAR EL EFECTO DE LA TEMPERATURA EN LA VIDA UTIL (DURACIÓN) DE FRUTAS Y HORTALIZAS DURANTE EL TRANSPORTE REFRIGERADO (Q10)

-

Modelo matemático para estimar la germinación interna de ajo chino en función de la temperatura de almacenamiento

-

PLANES DE MUESTREO

-

PRE TRIP INSPECTION (PTI) PARA CONTENEDORES REFRIGERADOS (MAERSK LINE)

-

LLENADO, ESTIBA Y TRINCADO DE CONTENEDORES – HAPAG LLOYD (Inglés)

-

Tratamiento con frío de frutas para control de insectos y plagas-USDA Cold Treatment Manual

-

CARRIER- CONTROLLED ATMOSPHERE HANDBOOK

-

Carrier Transicold: Manuales de Operación y Servicio (Inglés)

-

Manual de Fumigación USDA (Inglés)

-

Moisture Sorption Characteristics of Starchy Products: Oat Flour and Rice Flour

-

KINETICS OF COLOUR CHANGE IN DOUBLE CONCENTRATED TOMATO PASTE DURING THERMAL TREATMENT

-

Sorption characteristics of fermented cocoa powder (Theobroma cacao L.)

-

Water sorption isotherms of non-fermented cocoa beans (Theobroma cacao)

-

Kinetics of moisture adsorption during simulated storage of whole dry cocoa beans at various relative humidities

-

Sorption characteristics of peeled beans and shells of fermented and dry Trinitario cocoa beans (Theobroma cacao L.)

-

Determination of the physical properties of fermented and dried Venezuelan Trinitario cocoa beans (Theobroma cacao L.)

-

Water sorption characteristics of six row barley malt (Hordeum vulgare)

-

Composition and thermogravimetric characterization of components of Venezuelan fermented and dry Trinitario type cocoa beans (Theobroma cacao L.)

-

Water Sorption Isotherms of NPK 10-20-20/4 Muriate of Potash Fertilizer (Industrial and Eng Chem. Res.)

-

PHYSICAL-CHEMICAL CHARACTERISTICS AND FACTORS AFFECTING WATER SORPTION AND CAKING OF NPK 10-20-20 MOP (BAGFAS) FERTILIZER

-

PORT OF LA GUAIRA, VENEZUELA: MUD SLIDES DECEMBER 15-17, 1999

-

TEMPERATURA Y HUMEDAD RELATIVA AMBIENTAL EN VARIAS CIUDADES DE VENEZUELA /AMBIENT TEMPERATURE AND RELATIVE HUMIDITY IN VARIOUS CITIES OF VENEZUELA (In Spanish)

-

TRANSPORTATION OF PLANTAIN IN REEFER CONTAINERS*

-

PRODUCCIÓN Y TRANSPORTE MARÍTIMO DE PLÁTANO VERDE PARA LA EXPORTACIÓN: ESTUDIO DE UN CASO EN VENEZUELA (In Spanish)*

-

SOYBEAN MEAL: PREVENTION OF SPONTANEOUS COMBUSTION DURING MARITIME TRANSPORTATION AND STORAGE *

-

APPLICATION OF RISK ANALYSIS USING THE HACCP CONCEPT TO PREVENT LOSSES AND CLAIMS DURING MARINE TRANSPORTATION OF FROZEN FOODS IN REEFER CONTAINERS *

-

FUMIGATION OF FOODS IN TRANSIT WITH PHOSPHINE- FIRE RISK IN CONTAINERS AND BULK CARGO- STUDY OF CASES *

-

TRANSPORTE EN CONTENEDORES DE CACAO Y CAFÉ EN SACOS: PREVENCIÓN DE DAÑOS POR CONDENSACIÓN*

-

PREVENCIÓN DE DAÑOS POR CONDENSACIÓN EN EL TRANSPORTE MARÍTIMO*

-

INSECTOS FRECUENTES EN EL CACAO ALMACENADO*

-

PILFERAGE OF GRAIN CARGOES AT PUERTO CABELLO, VENEZUELA*